For Branding

Case Background

Who is Sheep Inc.

Business Challenges

Fast Fashion Leads to Pollution and Climate Change

Fast fashion has been a trend that changes the way we consume clothes which are mass-produced to meet people’s insatiable appetite, making the garment in your wardrobe have a shorter and limited lifespan when the newer and more stylish design is created. A 2021 report from the World Economic Forum said fashion and its supply chain, as the third largest polluter, releasing 5% of the world’s greenhouse gas emissions generated from raw materials to production and the processing of shipping to a customer’s hand. Let’s take a closer look at the material used to create a garment. The synthetic fibers, composing 65% of clothing, come from fossil fuels. Nearly 3.5 million barrels of crude oil are used each year in production.* On the other hand, the recycling and reuse of the textile is too slow to catch up with the consumption, making most of the discarded clothes end up in landfills. And burning of them leads to another factor that exacerbates global warning when more toxic substances are released to the atmosphere. Due to this, textile production has then undoubtedly contributed to climate change.

THE ACTIVITY WAS CHALLENGING, REQUIRED A HIGH LEVEL OF INNOVATION, AND DIRECT ACTION AND/OR EXTENSION TO ACHIEVE THE PLANNED OUTCOME

Following a road not yet made

Strategic Objectives

Bring Circular Economy to Textile Production

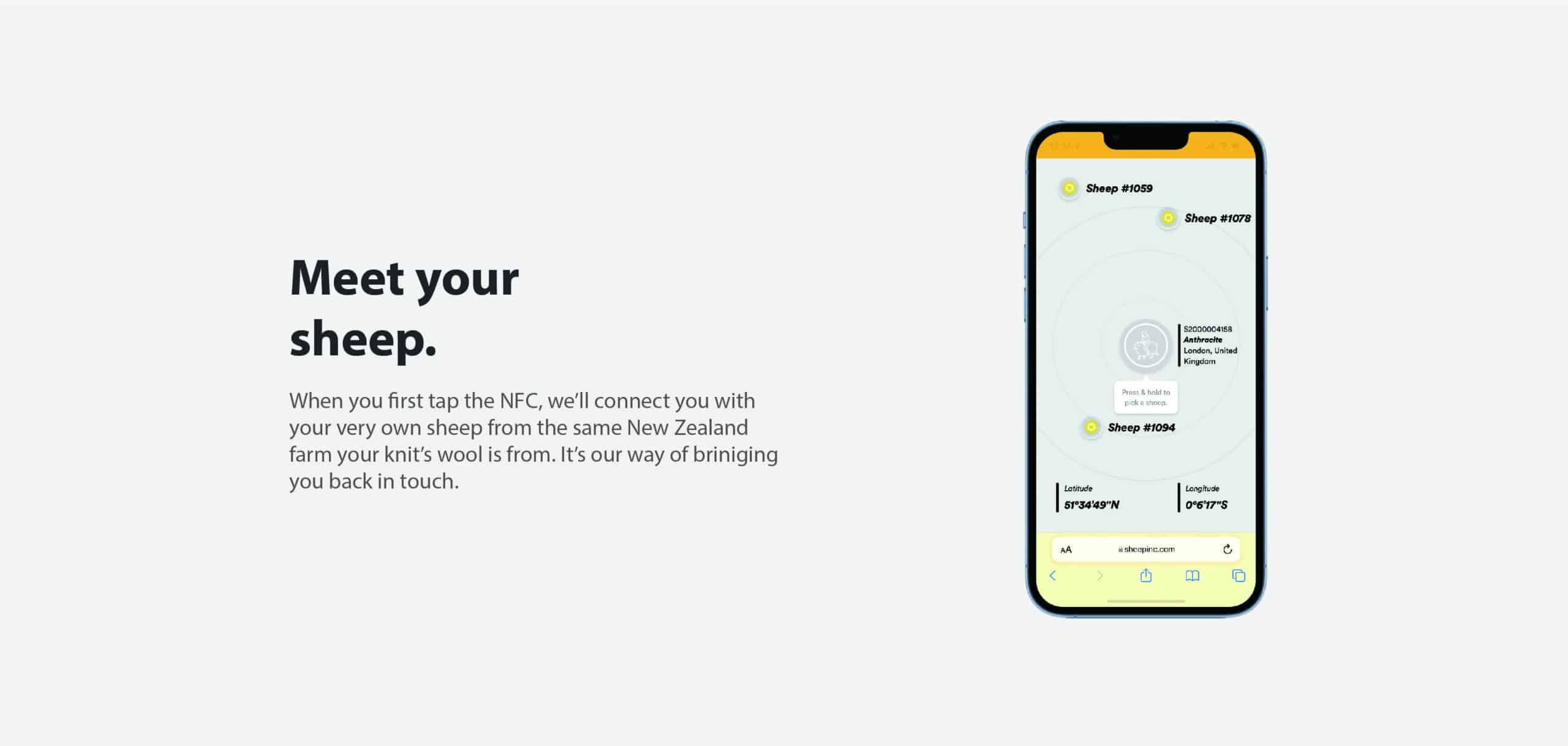

It is never too late to make a change to ensure clothing is durable and not disposable when a new business model is introduced to shift this trend. To make this happen, new technologies can bring the concept of circular economy from production to consumption into real shape when information on how the garment is created is accessible for the manufacturer and the customer. RFID can act as the enabler to realize the ambition to make a difference. This communication technology happens between a reader which generates a magnetic field from its antenna and a tag that can gain its power via coupling both in the proximity. Therefore, an RFID tag can be a battery-less device – small in size and cost-effective. Moreover, the value of RFID comes from each tagged item bearing an ID number so that data acquired facilitates the formation of an ecosystem that all parties involved can benefit from. That is to say, an RFID tag records all events during the production journey which gives visibility for the manufacturer in supply chain management. Meanwhile, consumers can get the information by their NFC-enabled phones to learn about the production history of their purchases. The brand owner can build a positive image in their marketing campaigns when a customer knows he/she is buying from someone who cares about the environment.

Product Solution

Your knitwear Can Tell You a Story

Business Benefits

Everything Connected Online and Offline for a Positive Future

THE ACTIVITY INVOLVED OTHER USERS OF THE ENVIRONMENT

The production and transport of food is a major global industry, and it is projected to grow strongly in Australia over the next 20 years as export capacities expand. In 2018, more than 23 million tonnes of foodstuffs worth $42 billion based on farm gate values passed through the Australian cold food chain. The TomKat KoolPak® is designed to assist producers deliver their products fresh and safe, and with the KoolPak App, they can also prove the provenance of their produce.

Spill over environmental benefits can also be attributed to the KoolPak for other sectors. Transport logistics have considerable environmental impact in the use of fuel, and emission of greenhouse gases. Existing polystyrene packaging is inefficient to transport to customers before they even use it. KoolPaks can be delivered by the pallet, flat packed for efficient transportation. Each pallet holds up to 140 KoolPaks which is approximately three times as many boxes as an equivalent sized polystyrene box or other option which is not flat packable.